Products Description

High Voltage 1.5W 9V EMC 3030 SMD LED Specs:

| Product name | High Voltage 1.5W 9V EMC 3030 SMD LED |

| Part number | GE-3030W400-3CZ-J2B2D0-R80 |

| Chips brand |

China Sanan 22*40mil or USA Bridgelux 22*40mil with 4 chips inside |

| Input |

8.6-9.2vdc voltage input; 150mA with 1.5W power rated; |

| Flux |

160-180lm/w at 1.5W 150mA; 220-240lm total flux; |

| Lighting Efficiency | 160-180lm/w at 1.5W 150mA; |

| Color |

2700K, 3000K, 4000K, 5000K, 5700K and 6500K available. CRI can be Ra>70, Ra>80 optional SDCM<5 with good lighting consistency; |

| Power |

Max drive 150mA at 1.5 Watt |

| Package material |

EMC flat package with copper |

| Lighting angle |

120 degree |

| Brand and manufacturer | GMLEDs, GMKJ |

| Warranty | 4 years |

| OEM service |

1. SKD parts available; 2. Aluminum pcb boards LED assembly service is also available here. |

Why we need to use 6v and 9v 3030 smd leds instead of 3vdc 3030 smd leds?

When designing LED lighting circuits, especially with high-power 3030 SMD LEDs, the decision to use 6V or 9V LEDs instead of 3V LEDs comes down to several key electrical advantages that make series connection more efficient and practical for larger, more complex LED arrays. Here's an explanation of why you would prefer 6V or 9V

3030 SMD LEDs connected in series rather than using 3V LEDs connected in parallel:

1. Efficiency in Voltage and Current Management

Series Connection with 6V or 9V LEDs: When LEDs are connected in series, the voltage across each LED adds up, but the current remains the same throughout the string. For instance, if you connect two 6V LEDs in series, the total voltage required is 12V, but the current flowing through each LED is the same. This makes power supply requirements easier to manage, especially when using higher voltage power sources (e.g., 12V or 24V).

Parallel Connection with 3V LEDs: When LEDs are connected in parallel, the voltage across all LEDs remains the same, but the current for each LED can vary, requiring individual current-limiting resistors or a sophisticated driver to ensure uniform current distribution. This can lead to inefficiency and higher costs in terms of components and complexity.

2. Reduced Current Load on Power Supply

Series Connection: With 6V or 9V LEDs, because the current stays constant across all LEDs in series, you can use a single constant current driver that powers the entire string of LEDs. This results in a more stable system with reduced stress on the power supply.

Parallel Connection: In parallel configurations, the current is divided among the branches, meaning each branch might draw different amounts of current, which can be inefficient and lead to overheating or the need for more robust (and expensive) power supplies.

3. Simpler and More Cost-Effective Drivers

Series Connection: Using higher voltage LEDs (6V or 9V) means you can use simpler, more cost-effective drivers. For example, a 12V or 24V power supply can drive multiple series-connected LEDs, eliminating the need for complex circuits that regulate current for each parallel branch.

Parallel Connection: With 3V LEDs in parallel, you would need a more complex constant-current driver for each individual LED or each parallel group to ensure even current distribution, adding to both the complexity and cost of the system.

4. Better Heat Dissipation

Series Configuration: Since the current remains constant in a series circuit, the heat generated by each LED tends to be more uniform, and the thermal management becomes easier. Higher voltage LEDs often have better thermal dissipation because they are designed for more robust applications.

Parallel Configuration: If each LED in parallel draws different currents, some LEDs might overheat due to uneven current distribution, potentially leading to failure or reduced lifespan.

5. Reduced Risk of Voltage Imbalance

Series Configuration: When LEDs are in series, if one LED fails, the entire series string will stop working, but at least you can easily detect the issue. Also, because each LED has the same current flowing through it, there's no risk of one LED drawing more current than the others, which can lead to premature failure in parallel connections.

Parallel Configuration: In a parallel configuration, if one LED fails or experiences a voltage drop, the other LEDs in the same branch may be affected, causing uneven brightness or overloading the driver.

6. Lower Complexity in Circuit Design

Series Connection: Using 6V or 9V LEDs in series reduces the need for additional components such as resistors or specialized drivers for current regulation, simplifying circuit design.

Parallel Connection: For 3V LEDs connected in parallel, the circuit design becomes more complicated due to the need for precise current control for each parallel branch, making it less efficient and more expensive to implement.

7. Increased Scalability

Series Connection: Series-connected LEDs are easier to scale up or down depending on the voltage of the power supply. You can easily add more LEDs to the series string if you need higher brightness, or reduce the number of LEDs if less light output is needed.

Parallel Connection: In parallel configurations, adding more LEDs can become more complicated because the current through each branch needs to be carefully balanced, requiring more sophisticated drivers.

Summary of Advantages for Using 6V/9V LEDs in Series:

Simpler power management: Easier to manage voltage and current with a single driver.

Cost-effective drivers: Easier to use standard voltage drivers (e.g., 12V or 24V) instead of complex current regulation systems.

Better heat management: More consistent heat dissipation and reduced risk of overheating.

Lower complexity: Fewer components are needed for a stable, efficient system.

Improved system reliability: Less risk of current imbalance and failure.

By using 6V or 9V LEDs in a series configuration, the overall system is more efficient, simpler to design, and easier to scale, which is why this approach is often preferred in high-power lighting applications like street lights, industrial lighting, or large LED panels.

High Voltage 1.5W 9V EMC 3030 SMD LED Picture:

High Voltage 1.5W 9V EMC 3030 SMD LED dimensions:

High Voltage 1.5W 9V EMC 3030 SMD LED specs:

|

Parameter |

Symbol |

Conditions |

Min |

Avg. |

Max |

Units |

|

Forward Voltage |

VF |

IF=150mA |

8.8 |

-- |

9.4 |

V |

|

Lighting efficiency |

IF=150mA |

160 |

180 |

Lm/W |

||

|

Luminous Flux |

Φv |

IF=150mA |

220 |

240 |

lm |

|

|

Color Temperature |

CCT |

IF=150mA |

-- |

4000 |

-- |

K |

|

Color tolerance |

IF=150mA |

-- |

-- |

5 |

SDCM |

|

|

CRI |

Ra |

IF=150mA |

80 |

-- |

-- |

-- |

|

Temperature Coefficient of Forward Voltage |

∆VF/∆T |

IF=150mA |

−− |

-2 |

−− |

mV/°C |

|

Reverse Current |

IR |

VR=15V |

−− |

−− |

10 |

μ A |

|

Viewing Angle |

2Θ1/2 |

IF=150mA |

−− |

120 |

−− |

Deg |

Application

High Voltage 1.5W 9V EMC 3030 SMD LED applications

High Voltage 1.5W 9V EMC 3030 SMD LED is mainly used for:

High-power 3030 SMD LEDs are used in applications requiring bright, efficient lighting:

Commercial & Industrial Lighting: Street lights, high-bay/low-bay lights, and floodlights for large spaces.

Automotive: Headlights, tail lights, and interior lighting.

Grow Lights: For indoor plant growth and horticulture.

Signage: Large-format LED displays and outdoor advertising.

Medical: Red light therapy for pain relief and skin care.

Backlighting: Used in LCD/LED TV displays.

Security: CCTV and security lighting for clear night surveillance.

About GMLEDs

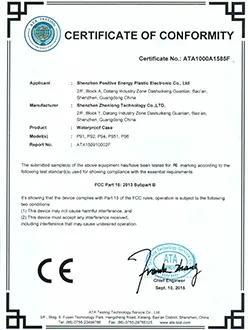

Certification available in GMLEDs

Guangmai Technology Certificaitions

CE

CE-LVD

FCC

ROHS

ISO9001

LM-80

About GMLEDs/GMKJ

Shenzhen Guangmai Electronics Co., Ltd., established in 2009 with a registered capital of 30 million RMB, is an enterprise specializing in the manufacturing of semiconductor packaging devices. Its subsidiaries include Shenzhen Guangmai Technology Co., Ltd., Guangmai Technology (Hong Kong) Co., Ltd., and Shenzhen OKAY Lighting Co., Ltd., forming a powerful corporate group. Guangmai Electronics is a national high-tech enterprise and a specialized and new enterprise in Shenzhen. It has been ranked among the top 100 in China's LED industry and has been awarded honors such as Shenzhen Standard Application Demonstration Unit and Guangdong Integrity Demonstration Enterprise.

Hot Tags: high voltage 1.5w 9v emc 3030 smd led, China, manufacturers, suppliers, factory, price, cheap, quotation, datasheet, specs, specification, green led diode, smd 5050 controller, smd 3535, royal blue power led, SMD 5050 RGBW, LED MCPCB Boards Soldering

![[[smallImgAlt]]](/uploads/31250/high-voltage-1-5w-9v-emc-3030-smd-leda145f.jpg)