405nm UV LED Chip Board for Ink Resin Dryer Specs

| Product name | 405nm UV LED Chip Board for Ink Resin Dryer |

| Part number | GM-20P400-5C4C-S1E5B |

| Chips brand | China Sanan 55mil chips with high radiation power |

| Input |

16-18vdc with max 4000mA current constant |

| Radiation power Intensity |

20000-25000mW |

| Lighting Efficiency |

UV invisiable light. It is meaningless to record the LPW data. |

| Color |

Below UV wavelength are available:

|

| Power |

Max 72 Watt |

| Package material | ALN ceramic substrated |

| Lighting angle |

120 degree quartz glass lens |

| Brand and manufacturer | GMLEDs, GMKJ |

| Warranty | 4 years |

| OEM service |

1. SKD parts available; 2. Customised LED array with the size you need is OK here. |

Why we need to use UV leds instead of Mercury lights for the UV curing industry?

The shift from mercury lamps to UV LEDs in the UV curing industry is driven by several key advantages:

1. Energy Efficiency & Cost Savings

UV LEDs consume 60-80% less energy than mercury lamps.

They turn on instantly at full power (no warm-up time), reducing idle energy waste.

Lower electricity costs and reduced cooling requirements improve overall efficiency.

2. Longer Lifespan & Lower Maintenance

Mercury lamps last 1,000–2,000 hours and degrade over time.

UV LEDs last 20,000–50,000 hours with consistent output, reducing replacement costs and downtime.

3. Environmental & Safety Benefits

No toxic mercury (mercury lamps require hazardous disposal).

No ozone generation (unlike mercury lamps, which emit ozone, requiring ventilation).

Reduced carbon footprint due to lower energy consumption.

4. Better Process Control & Performance

Instant on/off allows precise curing control.

Narrower wavelength options (e.g., 365nm, 385nm, 395nm) for optimized curing.

No infrared (IR) heat output, reducing substrate damage (ideal for heat-sensitive materials like plastics, films, and electronics).

5. Compact & Flexible Design

UV LED systems are smaller and lightweight, enabling integration into high-speed or portable curing systems.

Directional light output improves efficiency (no reflectors needed).

6. Regulatory Compliance & Future-Proofing

Many countries are phasing out mercury-based lighting (Minamata Convention).

UV LEDs align with sustainability goals and stricter environmental regulations.

Industries Benefiting from UV LEDs:

✅ Printing (inkjet, flexo, offset)

✅ Coatings & Adhesives

✅ Electronics (PCB, displays, encapsulation)

✅ Medical & Dental (bonding, sterilization)

✅ 3D Printing & Automotive

Conclusion:

UV LEDs outperform mercury lamps in efficiency, cost, safety, and performance, making them the future of UV curing technology.

405nm UV LED Chip Board for Ink Resin Dryer Picture

405nm UV LED Chip Board for Ink Resin Dryer dimensions

405nm UV LED Chip Board for Ink Resin Dryer Electrical Specs

|

Parameter |

Symbol |

Conditions |

Min |

Avg. |

Max |

Units |

|

Forward Voltage |

VF |

IF=4000mA |

16.00 |

-- |

18.00 |

V |

|

Thermal Resistance Junction To Board |

RΘJ-B |

IF=4000mA |

-- |

1 |

-- |

°C/W |

|

Radiant Flux |

Φe |

IF=4000mA |

20000 |

-- |

25000 |

mW |

|

Peak wavelength |

λp |

IF=4000mA |

400 |

-- |

405 |

nm |

|

Reverse Current |

IR |

VR=25V |

−− |

−− |

10 |

μ A |

|

Viewing Angle |

2Θ1/2 |

IF=4000mA |

−− |

120 |

−− |

Deg |

What is the application for 405nm UV LED Module?

405nm UV LED Module applications

The 405nm UV LED module falls within the near-UV spectrum (visible violet light with some UV properties) and is widely used across industries due to its unique wavelength characteristics. Here are the key applications:

1. UV Curing & Adhesive Bonding

Used for curing inks, coatings, and adhesives in:

3D Printing (SLA/DLP) – Cures photopolymer resins.

Electronics – Encapsulation, conformal coatings, and PCB bonding.

Medical Devices – Fast-curing medical adhesives.

Automotive & Aerospace – Structural bonding and protective coatings.

2. Printing & Packaging

Inkjet & Flexographic Printing – Cures UV-sensitive inks instantly.

Label & Packaging – High-speed curing on films, foils, and paper.

3. Optical & Laser Applications

Fluorescence Microscopy – Excites fluorescent dyes in bio-imaging.

Laser Diodes – Used in Blu-ray drives, laser engraving, and optical storage.

4. Counterfeit Detection & Forensics

Banknote & Document Verification – Reveals security marks and watermarks.

Forensic Analysis – Detects bodily fluids, fingerprints, and tampering.

5. Sterilization & Disinfection (Limited Use)

While less effective than 265nm UVC LEDs, 405nm has some bacteriostatic effects (used in air/water purification and medical surface treatment).

6. Industrial & Scientific Uses

Alignment & Inspection – Helps in precision manufacturing.

Photolithography – Used in semiconductor and microfabrication processes.

Why 405nm Instead of Other UV Wavelengths?

✔ Deeper penetration than shorter UV wavelengths (e.g., 365nm).

✔ Lower risk of material degradation (gentler on sensitive substrates).

✔ Compatible with many photoinitiators used in UV-curable resins.

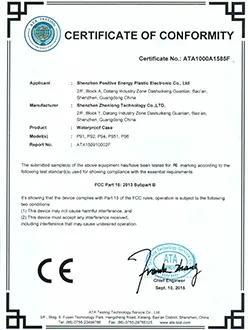

About GMLEDs

Certification available in GMLEDs

Guangmai Technology Certificaitions

CE

CE-LVD

FCC

ROHS

ISO9001

LM-80

About GMLEDs/GMKJ

Shenzhen Guangmai Electronics Co., Ltd., established in 2009 with a registered capital of 30 million RMB, is an enterprise specializing in the manufacturing of semiconductor packaging devices. Its subsidiaries include Shenzhen Guangmai Technology Co., Ltd., Guangmai Technology (Hong Kong) Co., Ltd., and Shenzhen OKAY Lighting Co., Ltd., forming a powerful corporate group. Guangmai Electronics is a national high-tech enterprise and a specialized and new enterprise in Shenzhen. It has been ranked among the top 100 in China's LED industry and has been awarded honors such as Shenzhen Standard Application Demonstration Unit and Guangdong Integrity Demonstration Enterprise.

Hot Tags: 405nm uv led chip board for ink resin dryer, China, manufacturers, suppliers, factory, price, cheap, quotation, datasheet, specs, specification, 100 watt cob led, yellow led chip, greenpower led, cob full spectrum, cree smd5050, deep red led

![[[smallImgAlt]]](/uploads/31250/405nm-uv-led-module-for-epoxy-resin-dryer612f6.jpg)